HPP TOLLING SERVICE

What is High Pressure Processing (HPP)?

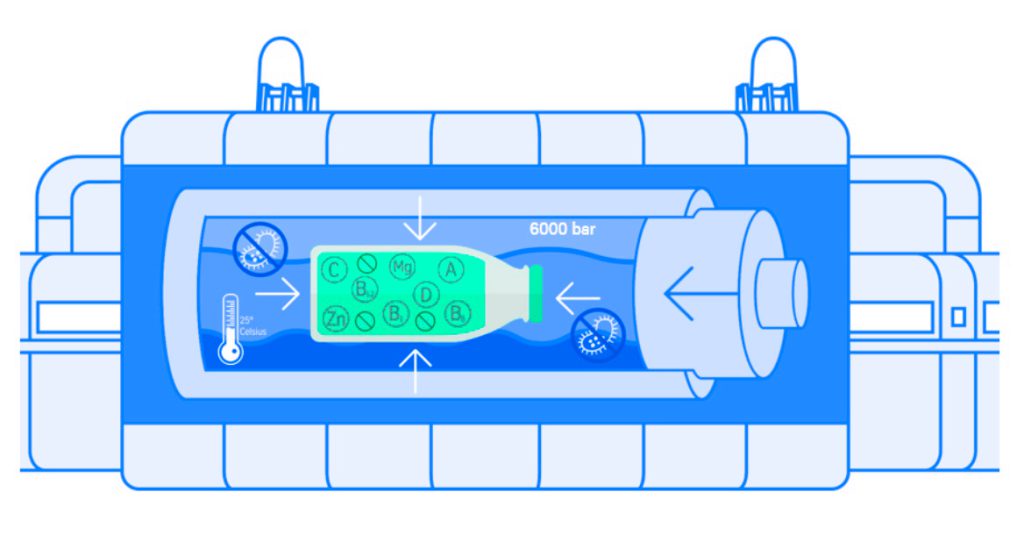

High pressure processing allows gentle preservation of food by high pressure without additives or heat. To achieve this, a pressure of 6,000 bar – which equals the pressure that might have at 60 km under the sea! – is applied to the products. The food is conveyed in special baskets into a high-pressure vessel. It then moves into the machine and is filled with water. Pumps increase the pressure in the vessel, which is applied both immediately and evenly spread leaving no evident crushing effect on the products. Once finished the pressure is reduced and your product has a much longer shelf life and maximum product safety.

How does High Pressure Processing preserve food?

Since high pressure eliminates many food-damaging organisms and can deactivate microorganisms, decay processes are significantly slowed down and in some cases even prevented.

Is HPP safe?

When it comes to food preservation there isn’t anything safer!

High Pressure Processing is the method that makes germs and bacteria harmless and preserve the taste and the vitamins. While unwanted microorganisms can survive even under conditions of extreme heat or cold, germs and bacteria are susceptible to changing pressure conditions and can be eliminated by applying pressure.

The result:

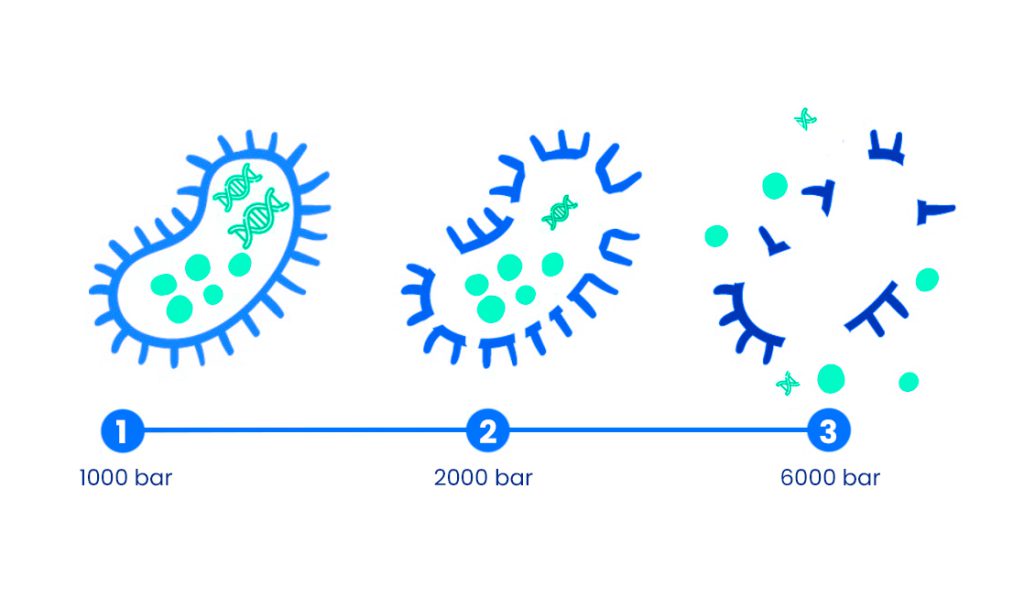

How does pressure inactivate bacteria?

HPP compromises cellular functions such as DNA replication, transcription, translation already at lower pressures (≤100 MPa) which impairs bacterial growth.

At higher pressures, microorganisms start suffering lethal injuries due to loss of cell membrane integrity and protein functionality. The most sensitive to pressures are molds, yeast and parasites. Inactivation of common bacteria requires higher pressure (300-600 MPa)

How does High Pressure Processing (HPP) affect shelf life?

HPP efficiently inactivate harmful microorganisms and enzymes leading up to 10 times longer shelf life.

HPP effect on inactivation of the same microorganism can vary from product to product. Storage temperature after HPP is also the factor that can influence shelf life of the product.

Water activity, pH value, fat or carbohydrate content can affect barsoresistancy of the microorganisms.